D2M’s multi-phase design strategy creates cutting-edge products that are functional, appealing, and manufacturable. This collaborative process, influenced by Stanford University’s approach to creative problem solving, is also highly adaptive to specific industries and situations. Fueled by curiosity, D2M can take your ideas from concept to final product or anything in between.

D2M’s multi-phase design strategy creates cutting-edge products that are functional, appealing, and manufacturable. This collaborative process, influenced by Stanford University’s approach to creative problem solving, is also highly adaptive to specific industries and situations. Fueled by curiosity, D2M can take your ideas from concept to final product or anything in between.

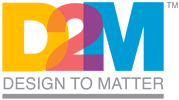

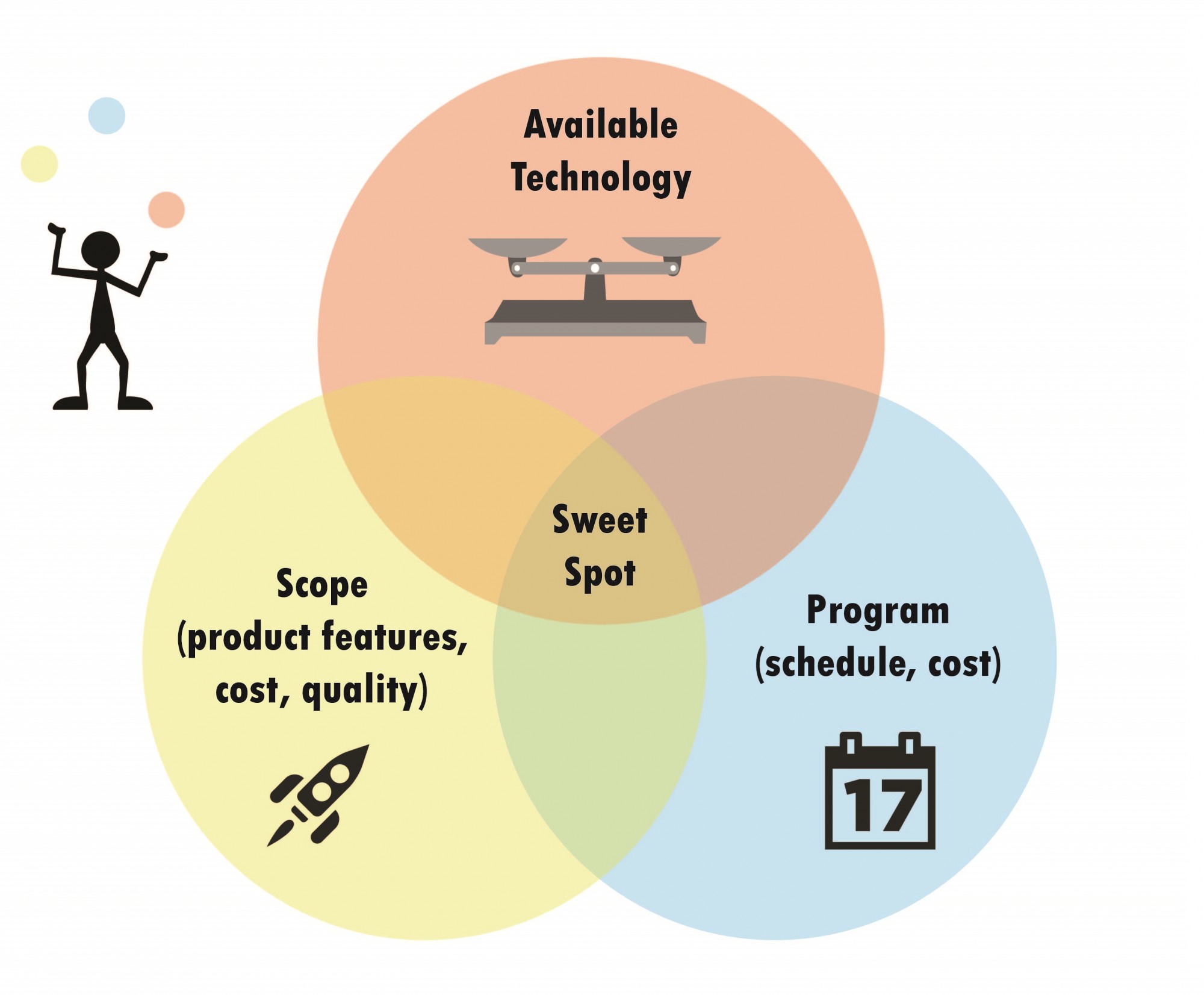

Product Concept Phase

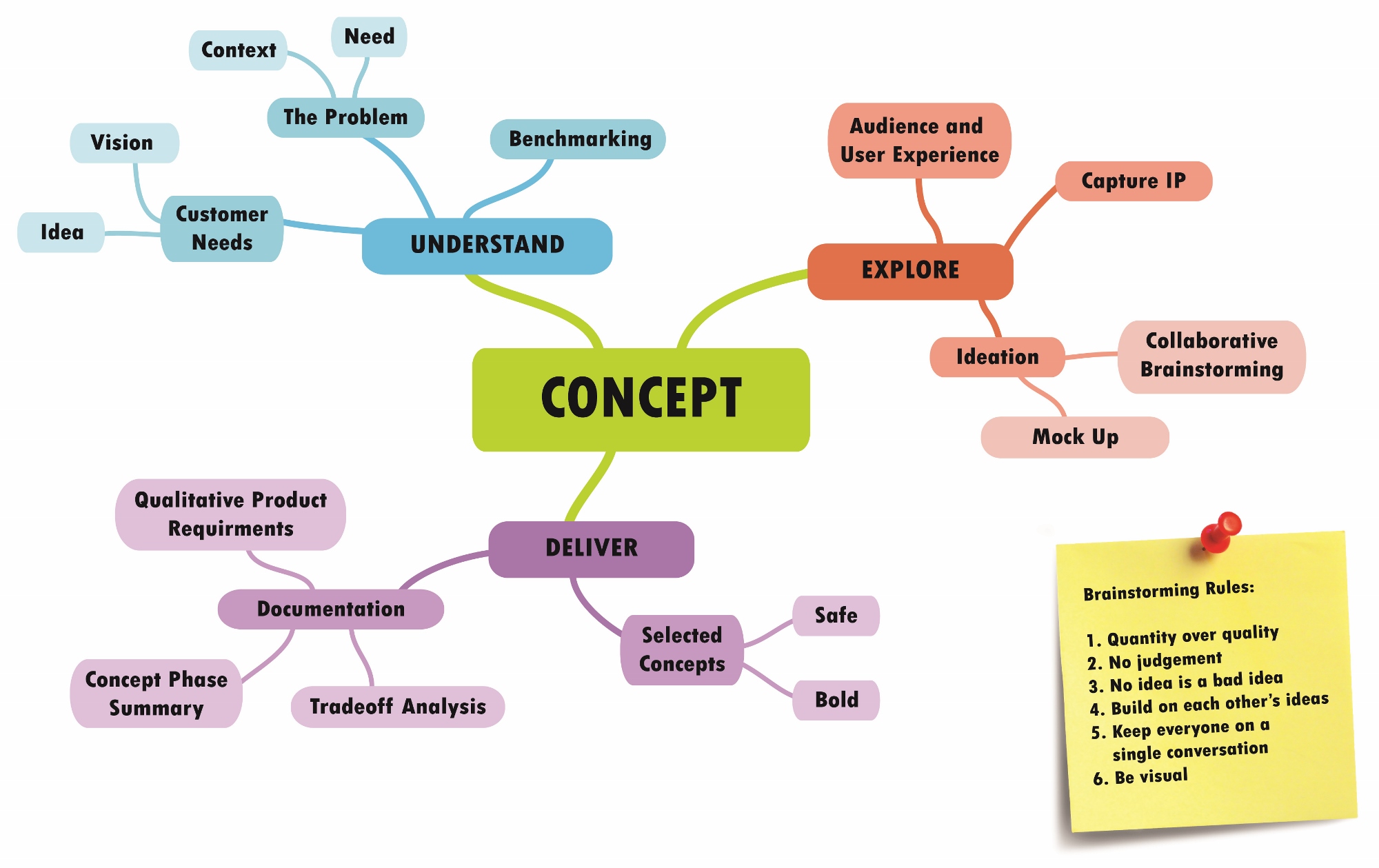

Design Architecture Phase

The product scope, program requirements, and available technology all contribute to the design process. These factors must be assessed and balanced to reduce development risk and maximize the opportunity for success.

During this phase, the manufacturability of the design is considered. This may require prototyping key subsystems and high risk design features. Lastly a game plan is made to take the product through the detailed design. This includes developing quantified engineering requirements that specify the target cost, characteristics, and functions of the product according to a given budget and schedule.

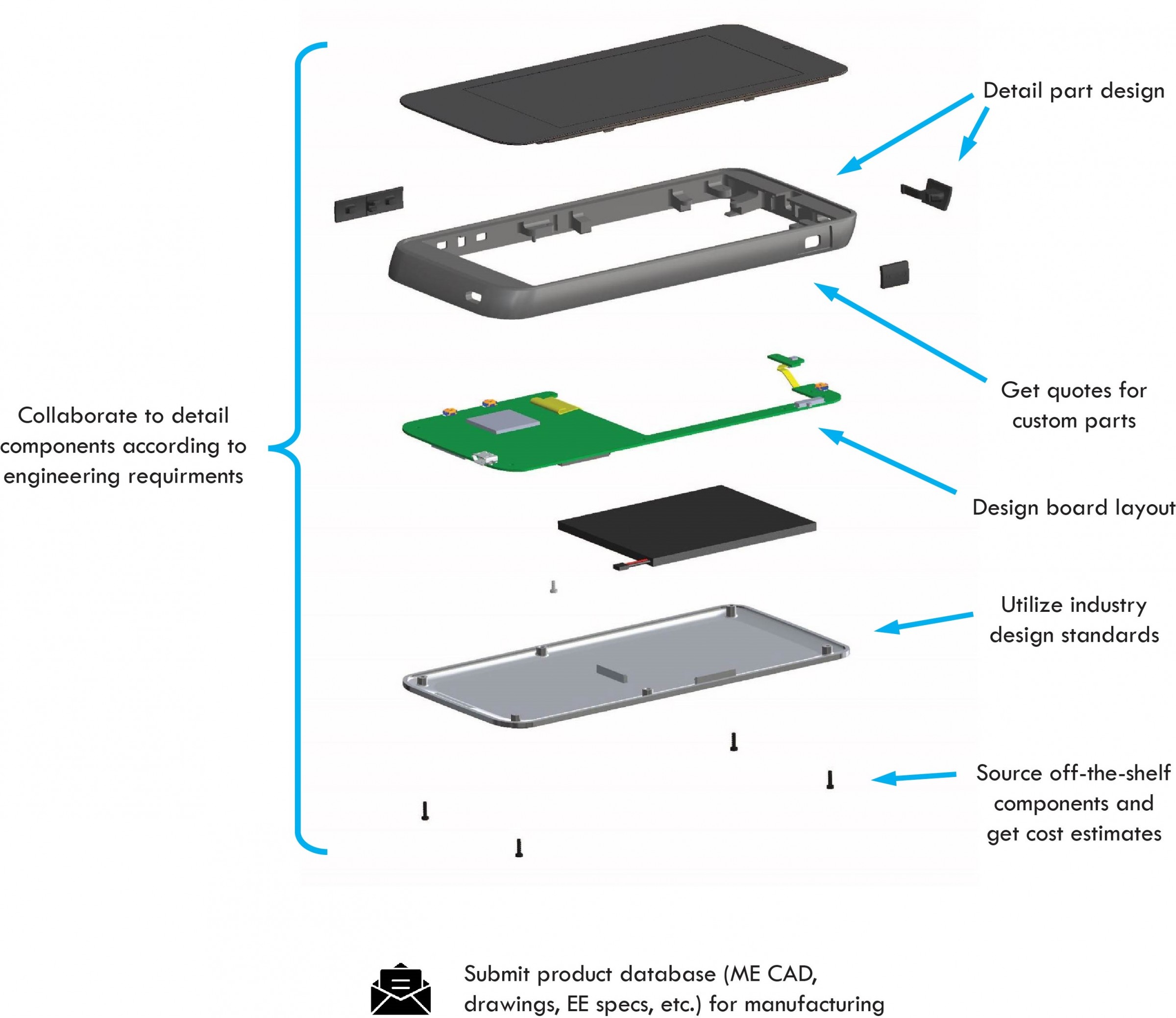

Detail Design Phase

During this phase the concept(s) and engineering requirements are used to create a detailed design that is ready for manufacturing. This requires an interdisciplinary effort between the ME and EE teams.

Verification

This is also known as the “testing and refinement” phase and allows us to:

- Prove design integrity by evaluating units with test fixtures and tools for debugging

- Set up a manufacturing process and production environment

- Understand performance and reliability of the product

- Identify necessary changes for the final product

Production

At this final stage, our blueprint has been completely implemented. To claim a successful development project, we:

- Assist in debugging and refining the pilot production process

- Achieve manufacturing goals on standard costs and yields

- Satisfy customer demands

- Respond to initial customer feedback

- Ship product!